When the Smith Family lived on their 100 acre farm in Palmyra they did many things to generate income. Each spring they tapped maple trees that grew naturally on their property. They tapped approximately twelve to fifteen hundred trees in a single season to produce an average of one thousand pounds of maple sugar and syrup. As missionaries sharing this story with visitors, we are naturally interested in the process of havesting maple sap, so we were excited about the opportunity to visit a local Maple Tree Syrup Farm while the maple sap was running. Here is what we learned:  A maple tree typically needs to be 40 years old before it is large enough to tap. A tree should be 10-15” in diameter for one tap. Each additional 5” in diameter allows another tap and tap holes are usually 7/16” diameter x 2-3” deep. In this picture (below) our guide is showing us how much more effective it is to drill the hole with a power drill, rather than a hand drill like it was originally done. The taps don’t hurt the tree as long as there aren’t too many per tree. Each year they make the holes in new areas on the tree.

A maple tree typically needs to be 40 years old before it is large enough to tap. A tree should be 10-15” in diameter for one tap. Each additional 5” in diameter allows another tap and tap holes are usually 7/16” diameter x 2-3” deep. In this picture (below) our guide is showing us how much more effective it is to drill the hole with a power drill, rather than a hand drill like it was originally done. The taps don’t hurt the tree as long as there aren’t too many per tree. Each year they make the holes in new areas on the tree.

A maple tree typically needs to be 40 years old before it is large enough to tap. A tree should be 10-15” in diameter for one tap. Each additional 5” in diameter allows another tap and tap holes are usually 7/16” diameter x 2-3” deep. In this picture (below) our guide is showing us how much more effective it is to drill the hole with a power drill, rather than a hand drill like it was originally done. The taps don’t hurt the tree as long as there aren’t too many per tree. Each year they make the holes in new areas on the tree.

A maple tree typically needs to be 40 years old before it is large enough to tap. A tree should be 10-15” in diameter for one tap. Each additional 5” in diameter allows another tap and tap holes are usually 7/16” diameter x 2-3” deep. In this picture (below) our guide is showing us how much more effective it is to drill the hole with a power drill, rather than a hand drill like it was originally done. The taps don’t hurt the tree as long as there aren’t too many per tree. Each year they make the holes in new areas on the tree.Once the hole is drilled a spout is inserted into the tree and a metal bucket is hung on the spout. Then a metal cover is placed over the bucket to keep bugs, sticks, etc out.

The maple sap is clear looking like water and is 98% water and 2% sugar. Each tap in a tree yields approximately 10 gallons sap annually. They say it has a slightly sweet taste in its sap stage. The sap runs from the roots to the top of the trees. When the days start getting warm the sap begins to run. In a good year, the days are warm and the nights are cold. The cold nights prevent the sap from running to to top of the tree too quickly and this lengthens out the season. When the sap reaches the top of the trees and the trees start to "bud out", the flavor of the sap becomes bitter and can not be used. This year we had many warm days and nights in a row right during the season, so this farmer only havested about 1/3 of his usual crop.

The maple sap is clear looking like water and is 98% water and 2% sugar. Each tap in a tree yields approximately 10 gallons sap annually. They say it has a slightly sweet taste in its sap stage. The sap runs from the roots to the top of the trees. When the days start getting warm the sap begins to run. In a good year, the days are warm and the nights are cold. The cold nights prevent the sap from running to to top of the tree too quickly and this lengthens out the season. When the sap reaches the top of the trees and the trees start to "bud out", the flavor of the sap becomes bitter and can not be used. This year we had many warm days and nights in a row right during the season, so this farmer only havested about 1/3 of his usual crop.  On this farm the family also uses a tube system for the trees on a slope. This system connects several trees together with tubes that are connected to the taps in each tree. This system uses gravity to help harvest the sap. At the lower end of the hill – or in this case the drumlin – there is a large storage container where the sap is collected from all of the trees connected through the tube system.

On this farm the family also uses a tube system for the trees on a slope. This system connects several trees together with tubes that are connected to the taps in each tree. This system uses gravity to help harvest the sap. At the lower end of the hill – or in this case the drumlin – there is a large storage container where the sap is collected from all of the trees connected through the tube system.

A person then collects this sap with a tractor that has a tank on the back. The sap from individual trees is collected this way too.

A person then collects this sap with a tractor that has a tank on the back. The sap from individual trees is collected this way too.  All of the sap is poured through a strainer, which is just a household sheet, to filter out sticks, bugs, etc.

All of the sap is poured through a strainer, which is just a household sheet, to filter out sticks, bugs, etc.

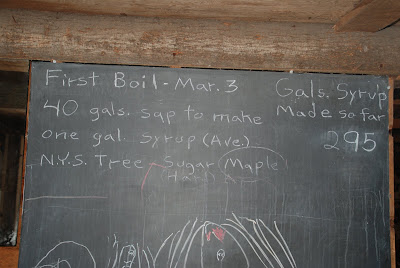

Once the sap enters the smokehouse, it passes into a 6’ x 16’ stainless steel wood fired evaporator where it is heated to boiling. As the sap is boiled and becomes more concentrated it turns darker in color. Pure Maple syrup is 1/3 water and 2/3 sugar and it takes 40 gallons of sap to make one gallon of syrup.

Once the sap enters the smokehouse, it passes into a 6’ x 16’ stainless steel wood fired evaporator where it is heated to boiling. As the sap is boiled and becomes more concentrated it turns darker in color. Pure Maple syrup is 1/3 water and 2/3 sugar and it takes 40 gallons of sap to make one gallon of syrup.

We also learned that Northeastern US and Canada are the only places in the world where Sugar Maples grow naturally. New York is the third largest producer of maple syrup. After taking this tour we gained a newer appreciation for the work the Smith Family did each spring while tapping their Sugar Maple Trees and boiling the sap into syrup and sugar.

We also learned that Northeastern US and Canada are the only places in the world where Sugar Maples grow naturally. New York is the third largest producer of maple syrup. After taking this tour we gained a newer appreciation for the work the Smith Family did each spring while tapping their Sugar Maple Trees and boiling the sap into syrup and sugar.

The maple sap is clear looking like water and is 98% water and 2% sugar. Each tap in a tree yields approximately 10 gallons sap annually. They say it has a slightly sweet taste in its sap stage. The sap runs from the roots to the top of the trees. When the days start getting warm the sap begins to run. In a good year, the days are warm and the nights are cold. The cold nights prevent the sap from running to to top of the tree too quickly and this lengthens out the season. When the sap reaches the top of the trees and the trees start to "bud out", the flavor of the sap becomes bitter and can not be used. This year we had many warm days and nights in a row right during the season, so this farmer only havested about 1/3 of his usual crop.

The maple sap is clear looking like water and is 98% water and 2% sugar. Each tap in a tree yields approximately 10 gallons sap annually. They say it has a slightly sweet taste in its sap stage. The sap runs from the roots to the top of the trees. When the days start getting warm the sap begins to run. In a good year, the days are warm and the nights are cold. The cold nights prevent the sap from running to to top of the tree too quickly and this lengthens out the season. When the sap reaches the top of the trees and the trees start to "bud out", the flavor of the sap becomes bitter and can not be used. This year we had many warm days and nights in a row right during the season, so this farmer only havested about 1/3 of his usual crop.  On this farm the family also uses a tube system for the trees on a slope. This system connects several trees together with tubes that are connected to the taps in each tree. This system uses gravity to help harvest the sap. At the lower end of the hill – or in this case the drumlin – there is a large storage container where the sap is collected from all of the trees connected through the tube system.

On this farm the family also uses a tube system for the trees on a slope. This system connects several trees together with tubes that are connected to the taps in each tree. This system uses gravity to help harvest the sap. At the lower end of the hill – or in this case the drumlin – there is a large storage container where the sap is collected from all of the trees connected through the tube system. A person then collects this sap with a tractor that has a tank on the back. The sap from individual trees is collected this way too.

A person then collects this sap with a tractor that has a tank on the back. The sap from individual trees is collected this way too.  All of the sap is poured through a strainer, which is just a household sheet, to filter out sticks, bugs, etc.

All of the sap is poured through a strainer, which is just a household sheet, to filter out sticks, bugs, etc.

It is then transported through an underground hose to one of three storage tanks that hold over 5,000 gallons of sap, combined.

Once the sap enters the smokehouse, it passes into a 6’ x 16’ stainless steel wood fired evaporator where it is heated to boiling. As the sap is boiled and becomes more concentrated it turns darker in color. Pure Maple syrup is 1/3 water and 2/3 sugar and it takes 40 gallons of sap to make one gallon of syrup.

Once the sap enters the smokehouse, it passes into a 6’ x 16’ stainless steel wood fired evaporator where it is heated to boiling. As the sap is boiled and becomes more concentrated it turns darker in color. Pure Maple syrup is 1/3 water and 2/3 sugar and it takes 40 gallons of sap to make one gallon of syrup.We also learned about how maple syrup is graded:

Grade A Light Amber is delicate flavor (far left)

Grade A Medium Amber is mild flavor

Grade A Dark Amber is full flavor

Extra Dark is a heavy flavor (far right)

Light Amber used to be the most popular, but now Extra Dark is becoming more popular.

When we saw how much work goes into making pure maple syrup, we began to understand why it is so costly. There is much work to do year round to prepare for the 4 to 6 week season of harvest. For example, it takes about 100 cords of wood each year to keep the fires going during the harvest season. The wood shed we are standing in was full, along with other stacks of wood used to feed the fire.

When we saw how much work goes into making pure maple syrup, we began to understand why it is so costly. There is much work to do year round to prepare for the 4 to 6 week season of harvest. For example, it takes about 100 cords of wood each year to keep the fires going during the harvest season. The wood shed we are standing in was full, along with other stacks of wood used to feed the fire.

Grade A Light Amber is delicate flavor (far left)

Grade A Medium Amber is mild flavor

Grade A Dark Amber is full flavor

Extra Dark is a heavy flavor (far right)

Light Amber used to be the most popular, but now Extra Dark is becoming more popular.

When we saw how much work goes into making pure maple syrup, we began to understand why it is so costly. There is much work to do year round to prepare for the 4 to 6 week season of harvest. For example, it takes about 100 cords of wood each year to keep the fires going during the harvest season. The wood shed we are standing in was full, along with other stacks of wood used to feed the fire.

When we saw how much work goes into making pure maple syrup, we began to understand why it is so costly. There is much work to do year round to prepare for the 4 to 6 week season of harvest. For example, it takes about 100 cords of wood each year to keep the fires going during the harvest season. The wood shed we are standing in was full, along with other stacks of wood used to feed the fire.

We also learned that Northeastern US and Canada are the only places in the world where Sugar Maples grow naturally. New York is the third largest producer of maple syrup. After taking this tour we gained a newer appreciation for the work the Smith Family did each spring while tapping their Sugar Maple Trees and boiling the sap into syrup and sugar.

We also learned that Northeastern US and Canada are the only places in the world where Sugar Maples grow naturally. New York is the third largest producer of maple syrup. After taking this tour we gained a newer appreciation for the work the Smith Family did each spring while tapping their Sugar Maple Trees and boiling the sap into syrup and sugar.

.jpg)

That's Great. We read Miracles on Maple Hill in book club a few years ago and it's nice to see the book come to life.

ReplyDelete